How to evaluate the sterilization effect of UV LED

The novel coronavirus pneumonia diagnosis and treatment plan (Trial) Fourth Edition, published by the National Health Protection Commission and the State Administration of traditional Chinese medicine in January 28, 2020, is described as follows: the virus is sensitive to ultraviolet and heat. Novel coronavirus (2019-nCoV) can be killed by ultraviolet rays.

With the improvement of UV LED power and technology, it has gradually replaced the lower power UV mercury lamp by the advantages of safety, environmental protection, small size and no chemical residue in the market.Through the summary of previous UV LED sterilization test cases, Jinjian laboratory found that brand, lamp bead lamp type, wavelength, luminous efficiency, irradiation distance, irradiation time, radiation intensity, penetration rate and application field are the influencing factors of disinfection and sterilization identification test results of UV-LED different from ultraviolet mercury lamp.

In this paper, we list three experiments to illustrate the importance of several factors, and suggest that customers evaluate the germicidal efficacy of UV-LED lamps according to different scientific experimental conditions in product performance and application field.

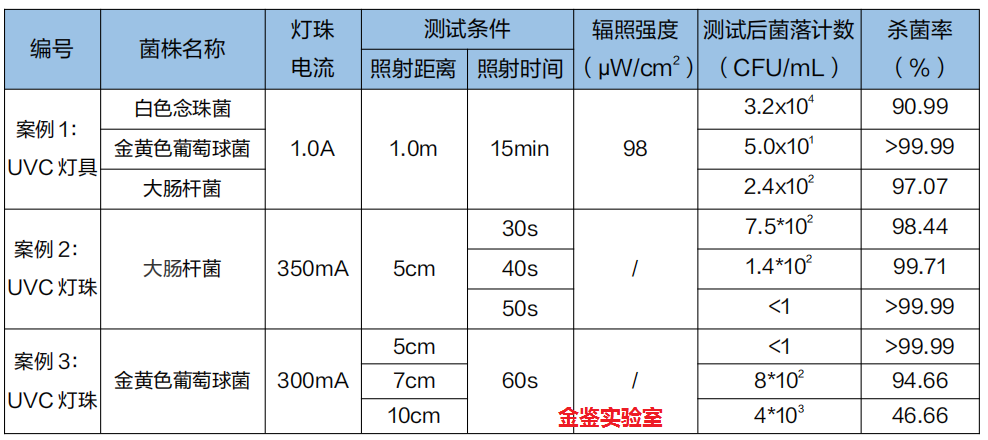

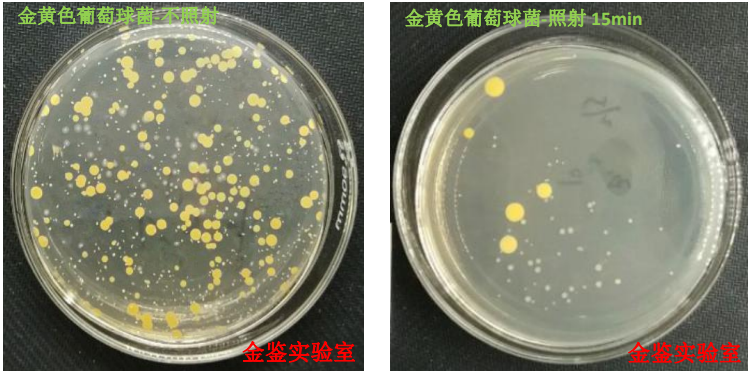

1、 Comparison of germicidal efficacy of the same product to different strains

A client entrusts Jinjian laboratory to carry out sterilization test on UV LED lamps. The center wavelength of the lamp was 275 nm, and the radiation intensity was 98 μ w / cm 2 at the irradiation distance of 1 m. The sterilization effect of the lamp on Candida albicans, Staphylococcus aureus and Escherichia coli was evaluated after 15 minutes of vertical irradiation. The test results showed that although the same UV LED radiation intensity, but the sterilization effect of different strains is different.

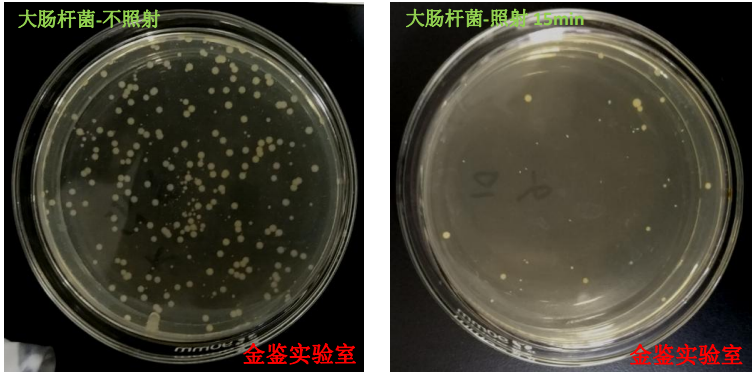

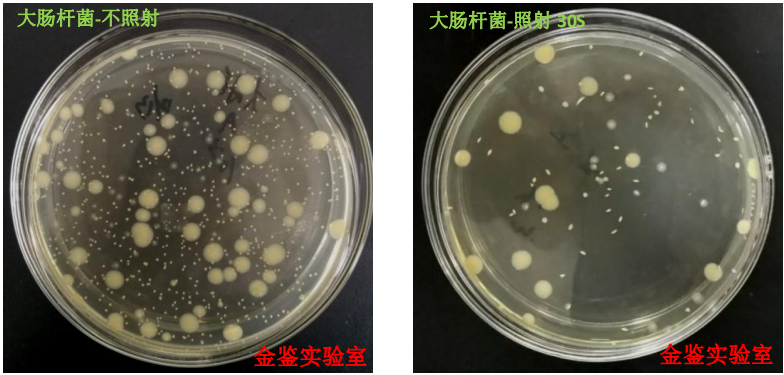

2、 Comparison of the effects of different exposure time on the same product

A client entrusts Jinjian laboratory to carry out sterilization contrast test on UV LED lamp beads under different conditions. The center wavelength of the sample UV LED lamp beads was 280nm, which was vertically irradiated for 30s, 40s and 50s from the top of the culture medium to evaluate its bactericidal effect on Escherichia coli. This test shows that under the same irradiation distance, the sterilization effect of UV LED is obviously enhanced with the increase of irradiation time. This UV LED UV lamp has good germicidal effect on Escherichia coli after irradiation for 50s. The test results are as follows:

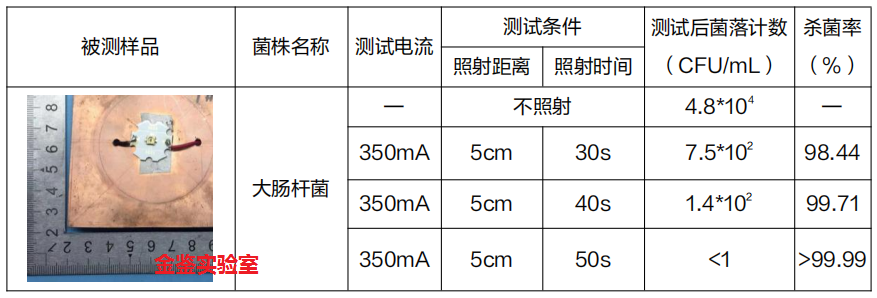

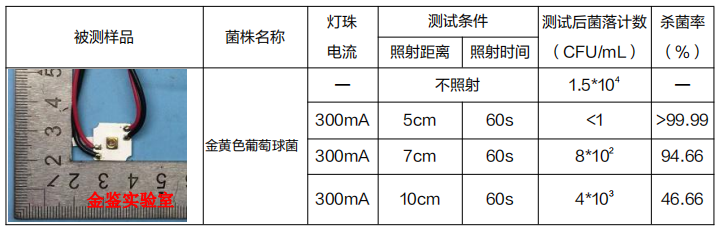

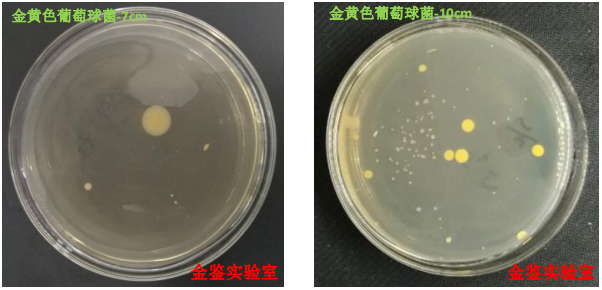

3、 Comparison of the effects of different irradiation distances of the same product

A client entrusted Jinjian laboratory to carry out sterilization test on UV LED lamp beads, and the central wavelength of UV LED lamp beads was 275 nm. The germicidal efficacy of Staphylococcus aureus was evaluated after irradiation for 60s at 5cm, 7cm and 10cm above the medium. In this experiment, UV LED UV lamp in the same irradiation time, with the increase of distance, the bactericidal effect decreased significantly; when the distance was 5cm, it had good bactericidal effect on Staphylococcus aureus. The test results are as follows:

Compared with the traditional ultraviolet lamp, Jinjian laboratory thinks that the following differences should be considered in the design of UVLED sterilization experiment:

1. Band:The killing effects of ultraviolet rays on bacteria and viruses are different. The traditional ultraviolet mercury lamp produces ultraviolet radiation with the wavelength of 253.7nm by discharge. However, according to the latest research results, the sterilization effect of ultraviolet ray may be higher near 264 nm. In terms of sterilization and disinfection of deep UV UVC led, standardization faces a series of challenges. For example, the sterilization of UV mercury lamp is mainly at 253.7nm, while UVC led wavelength is mainly distributed in 200-280nm, which brings a series of differences for the follow-up application solutions.

2. UV dose:Sufficient irradiation time and sufficient intensity are needed. The intensity of ultraviolet radiation depends on the luminous intensity of the effective spectrum in the ultraviolet light source, the light output angle of the lamp (beam concentration), and the distance between the lamp and the object being radiated. Generally speaking, the higher the radiation intensity, the better the effect; the more focused the beam on the surface of the radiated object, the better the sterilization effect; the closer the beam is to the radiated object, the better the effect; the cumulative radiation time, that is, the longer the total radiation time of the irradiated object under the ultraviolet lamp, the better the effect.

3. Luminous efficiency:At present, ultraviolet LED can not completely replace mercury lamp in terms of luminous efficiency. UVA & nbsp; LED technology has been relatively mature, EQE can reach 50-60%. For UVA products, more work will focus on the development of application system level in the future. The external quantum efficiency of UVB and UVC band deep ultraviolet LED is still relatively low, EQE is generally below 10%, and commercial products are basically 1% ~ 3%.

4. Application fields:UV LED also has the advantages of small and portable, environmental safety, easy to design and so on, which can give birth to some application requirements different from the traditional mercury lamp. For example, portable electronic disinfection products, elevator handrail sterilizer, sweeping robot and so on have appeared. This is where traditional UV light sources are difficult to use.

5. Ultraviolet penetration:UV LED has a good inactivation effect on the surface of the object directly irradiated, but its penetration is not strong, and it has no obvious effect on the interior and covered parts of objects that cannot be penetrated by light. However, the traditional ultraviolet lamp can make up for the defects of dead angle caused by ultraviolet ray only propagating along a straight line and disinfection.

6. Sterilization difference:Different brands and specifications of ultraviolet lamps have great difference in sterilization. When purchasing, it is necessary to confirm the radiation wavelength, radiation intensity, protection design and working requirements of the light source, and select appropriate lamps and lanterns.

As a third-party laboratory specialized in LED quality management, Jinjian laboratory has passed the certification of CMA, CNAs and ISO 9001 quality management system, etc., and has launched the service project of "UV LED UV sterilization experiment" to the market.According to the brand, lamp type, wavelength, luminous efficiency, irradiation distance, irradiation time, radiation intensity, penetration rate, application field and other factors affecting the results of disinfection and sterilization identification, the experimental scheme was designed jointly with customers to scientifically evaluate the sterilization effect of UV-LED UV lamps.

The optimized test scheme is as follows

1. Comparative test of different strains

2. Comparative test of germicidal efficacy at different irradiation distances

3. Comparative test on germicidal efficacy of different irradiation time

4. Comparative test on germicidal efficacy of different radiation intensity

5. Comparative test of different products under the same test conditions

......

Test strains:Staphylococcus aureus, Escherichia coli, Pseudomonas aeruginosa, Staphylococcus albicans, Mycobacterium Chelonii subsp. Abscessus, Bacillus subtilis var. niger spores, Candida albicans, etc.

Staphylococcus aureus was the representative of Staphylococcus aureus;

E. coli 8099 is the representative of intestinal bacteria in bacterial propagulum;

Pseudomonas aeruginosa ATCC 15442 is the representative of the most commonly isolated bacterial propagules in nosocomial infection;

Staphylococcus albus 8032 is the representative of bacteria in the air;

ATCC 93326 is the representative of Mycobacterium tuberculosis;

The spore ATCC 9372 of Bacillus subtilis var. Niger is the representative of bacterial spores;

Candida albicans ATCC 10231 is the representative of pathogenic fungi.

Executive standard:Technical specification for disinfection, GB 28235-2011 safety and health standard for ultraviolet air disinfector, hj2522-2012 technical requirements for environmental protection products, ultraviolet disinfection device, wst367-2012 technical specification for disinfection of medical institutions, and enterprise standard of Jinjian laboratory.

Appendix:

1、 Advantages of deep UV UV LED sterilization:

1. High efficiency sterilization:The sterilization and inactivation of bacteria and bacteria is usually completed in a few seconds, almost instantaneously.

2. Broad spectrum of sterilization:It can kill almost all bacteria and viruses efficiently.

3. No secondary pollutionNo other chemical pollutants were produced.

Click to view:Bactericidal efficiency of deep ultraviolet light on common bacteria and viruses

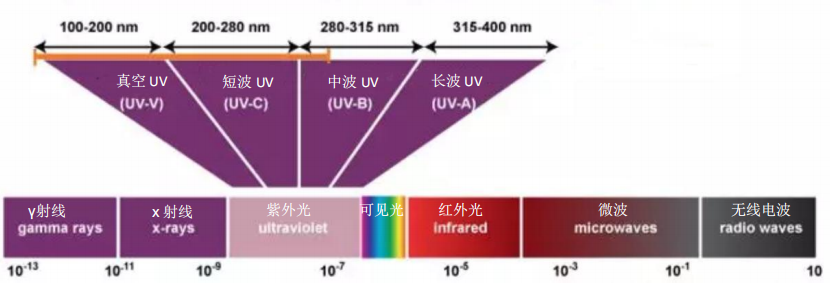

2、 Classification of ultraviolet bands;

According to the wavelength division of UV band:

UVA: 315-400nm (near UV nuv365-400nm), applications include curing, photocatalytic purification, anti-counterfeiting and other fields.

UVB: 280-315nm, applications include photohealth / medical, plant growth, light regulation, etc.

UVC: 200-280nm (solar blind ultraviolet), used for disinfection of water and air.

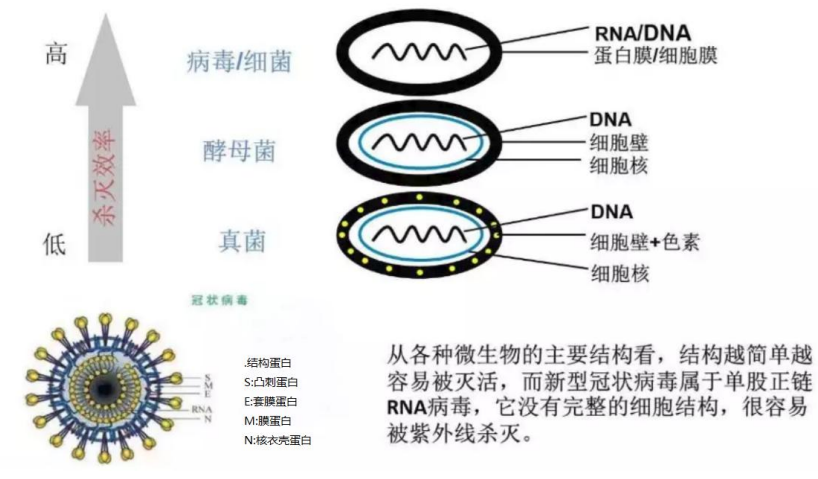

3、 Principle of ultraviolet disinfection

UV disinfection technology is based on the research foundation of modern epidemic prevention, medicine and photodynamic, using specially designed UVC band ultraviolet lamps with high efficiency, high intensity and long life. Ultraviolet radiation damages and destroys the function of nucleic acid to microorganisms (bacteria, viruses, spores and other pathogens) so as to kill microorganisms and achieve the purpose of disinfection and sterilization. The inactivation effect depends on the ultraviolet radiation dose.

Microbial structure and UV inactivation mechanism

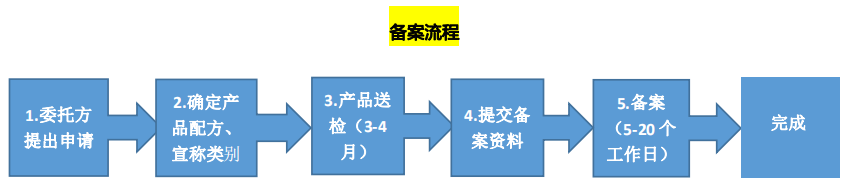

4、 Category I and II disinfection products

The national health and Family Planning Commission (nhfpc) has issued corresponding policies, requiring the first and second class disinfection products to carry out health and safety evaluation by themselves or by a third party before they are put on the market for the first time, and the disinfection products that pass the evaluation can be sold on the market. That is to say, it is necessary to entrust a third-party testing and evaluation institution to carry out health and safety evaluation, issue professional test report and put on record by the government before the product can be sold on the market.

Category I disinfection productsStrict and effective disinfection means that the products need to be managed effectively. It includes high-level disinfectants and disinfection devices, fungicides and sterilization devices for medical devices, skin and mucous membrane disinfectants, biological indicators and chemical indicators of germicidal efficacy.

Category II disinfection productsIt refers to disinfection products with moderate risk and need to be strengthened management to ensure safety and effectiveness, including disinfectants, disinfection instruments, chemical indicators, packaging materials and anti bacteria preparations with sterilization marks except for the first category of products.

Comparison of driving circuits for deep UV uvc-led

Technology sharing · July 3, 2019 · 2664 views

Development of deep UV LED

Technology sharing · December 6, 2020 · 1318 views

Zhang Hao: evaluation and application of UVA led photocatalysis technology for air sterilization and disinfection

Industry Information · February 15, 2020 · 1113 Views

Biological safety of 222 nm lamp for sterilization

Industry Information, December 19, 2020, viewed 2091 times

Hubei Daily: Chen Changqing, founder of the company

Media reports, April 1, 2019, 1141 views

Over flow dynamic water sterilization, more than 99% -- deep UV LED

Technology sharing · July 24, 2018 · 570 views

Win win cooperation! Professor Ye Jichun and associate researcher Guo Wei of Ningbo Institute of materials, Chinese Academy of Sciences visited our company

Company News, July 31, 2018, 1604 views

Ultra clean semiconductor plant of szech technology put into operation

Company News, February 10, 2018, 1982 views